Linen: Ideal Summer Fabric for Designer Brands

Discover why linen is the ultimate summer fabric for designer labels—learn about quality factors, weaves, blends, and expert sourcing by Jodkar Fashion.

We work with you to refine your ideas and align them with production feasibility while maintaining your vision.

Choose from finest fabrics, with natural dyes or azo-free dyes, and premium trims to match your design aesthetic.

Bring your designs to life with detailed sampling and precise patterns to ensure perfection before production.

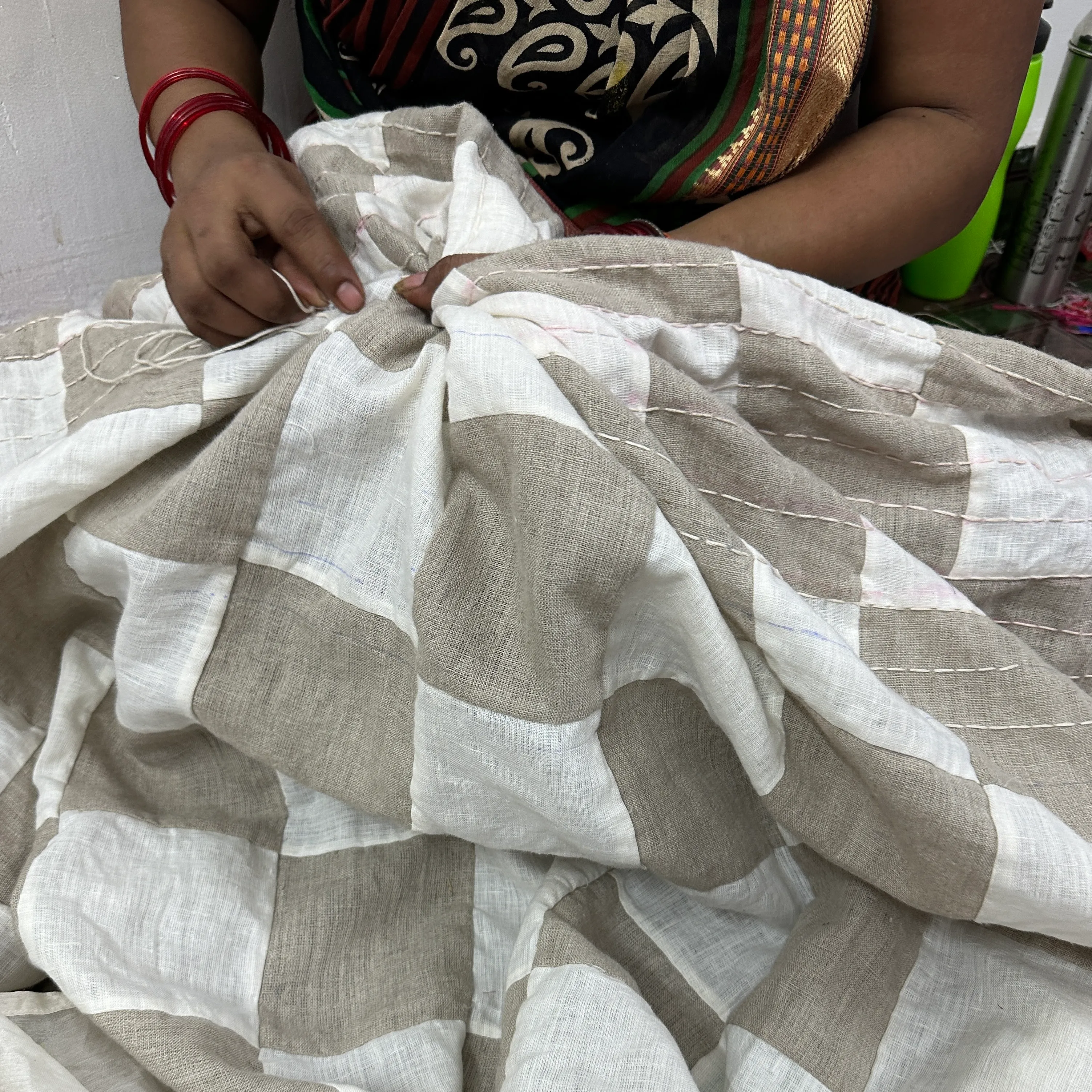

From delicate seams to structured garments, our expert team ensures each stitch meets your exacting standards.

We offer hand embroidery and machine-assisted precision for truly unique, high-quality designs.

Our zero-waste approach transforms production leftovers into beautiful, sustainable garments, ensuring environmental responsibility.

Achieve consistent, professional-grade results with our meticulous processes, designed to uphold the highest standards for your brand.

Showcase timeless elegance with intricate handcrafting by Lucknow's artisans, blending tradition with precision.

Transform your designs into eco-friendly masterpieces with our zero-waste processes, upcycled textiles, and natural dyes.

Empower your brand's growth with low MOQs and adaptable processes, perfect for experimenting and scaling effortlessly.

Meet tight deadlines with our efficient processes that guarantee precision, quality, and on-time delivery every time.

From concept to creation, we provide seamless support at every stage, ensuring your vision is brought to life flawlessly.

Jodkar Fashion Private Limited was born out of a vision to transform the fashion industry into a more sustainable, ethical, and creative space. Our founder, Anshika, a graduate in Fashion Design, was deeply appalled by the sheer waste generated during her first job in the industry. Witnessing piles of discarded materials and inefficient processes, she felt compelled to take action. Determined to create change, she began her journey to redefine garment manufacturing—combining her design expertise with a commitment to sustainability and zero-waste practices.

Our MOQ is 15 pieces per color, per design, with mixed sizes. Subject to design and fabric constraints.

Our typical timeline is 2-3 weeks for sampling, and 4 weeks for production batches.

Yes, our team of expert designers is happy to lend a hand if needed, offering guidance with design development and prototyping.

We champion zero-waste processes, upcycling up to 80% of scraps, and using natural fabrics and eco-friendly dyes. Our commitment to blending sustainability with exceptional craftsmanship sets us apart.

We create upcycled garments from fabric scraps, use natural biodegradable fabrics, and employ eco-friendly dyes, ensuring waste reduction and resource efficiency.

We follow a multi-step QC process, ensuring inspections at each stage—from checking fabrics for defects and controlling dye colors to inspecting final stitching for quality. Rework is conducted as needed to guarantee excellence.

We follow a transparent tiered payment plan: 50% of the invoice value as advance, and the remaining 50% before dispatch after inspecting the garments either on-site or via high-resolution images and videos shared by our team.

Yes, absolutely. Visits can be scheduled by speaking to your sales representative. Unfortunately, we cannot accommodate walk-ins.

Yes, we work with leading last-mile shipping partners such as DHL, FedEx, Aramex, and Maersk to ensure hassle-free delivery.

We're very flexible with custom designs and encourage creativity. For last-minute changes, it depends on the stage of production, but we will work closely with you to find the best possible solution.